Global Printing Plate Market Expands with Innovation, New Entrants, and Evolving Printing Technologies

The Printing Plate Market grows as established players and new entrants adopt advanced technologies to meet global printing demand.

NEWARK, DE, UNITED STATES, August 28, 2025 /EINPresswire.com/ -- The global printing plate market is undergoing a dynamic transformation, driven by technological innovation, a rising demand for high-quality printing, and an expanding ecosystem of both established manufacturers and ambitious new entrants. From packaging and food industries to pharmaceuticals, cosmetics, and automotive applications, printing plates are proving to be an indispensable component in modern branding and product communication strategies.

Printing Plates: The Foundation of Precision Printing

Printing plates play a critical role in traditional and modern printing processes. Acting as the “image carrier,” they ensure that images and texts are accurately transferred to the chosen substrate, whether film, foil, plastic, or board. Common processes such as flexography, lithography, gravure, and letterpress rely heavily on photopolymer plates that combine durability with precision.

At their core, printing plates are engineered to deliver:

- Deep-relief imagery for sharper and cleaner results with reduced wash-ups.

- Dimensional stability for accurate register during high-volume printing runs.

- Superior ink transfer that enhances consistency across substrates.

- Durability and long life, enabling longer press runs without compromising quality.

These benefits make them essential to converters, printers, and manufacturers worldwide who seek to combine quality with efficiency.

Request Printing Plate Market Draft Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-10382

Market Dynamics: Innovation Driving Growth

The printing plate market is witnessing rapid innovation as manufacturers respond to evolving industry needs. A major focus has been on creating solutions that support ultraviolet (UV) inks without requiring additional post-bake processing. For example, Kodak introduced two pioneering technologies—one based on negative working plates and another on positive working plates—tailored to handle the challenges posed by UV inks and related press chemistries.

Similarly, FUJIFILM Holdings America Corporation has been at the forefront of developing plates with improved resistance, longer life cycles, and reduced chemical processing requirements. Flint Group and MacDermid Inc. continue to expand their portfolios with products aimed at sustainability, addressing industry concerns about chemical waste and water usage.

Flexographic printing has emerged as the fastest-growing technology in recent years. Its ability to print on diverse materials with a wide range of inks has made it the preferred choice for industries like food packaging, pharmaceuticals, and personal care. Printing plates designed for flexography enable high-speed operations while ensuring exceptional image quality—a win-win for manufacturers and consumers alike.

Challenges and Opportunities

While the printing plate market outlook remains positive, it is not without challenges. Plate processing traditionally requires significant resources—chemicals, water, and energy—while also generating waste in the form of spent chemistry and wastewater. Environmental regulations are increasingly strict, pushing manufacturers to invest in eco-friendly alternatives.

This challenge, however, presents an opportunity. Companies that can deliver sustainable, low-waste printing plates stand to capture market share as businesses and regulators prioritize environmental responsibility. Already, several manufacturers are exploring water-washable and thermal plates that significantly reduce chemical dependency.

Established Leaders and Emerging Innovators

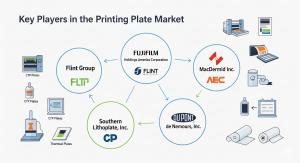

The market is shaped by a mix of global leaders and new entrants striving to capture growth. Prominent companies include:

- FUJIFILM Holdings America Corporation – Known for pioneering prepress innovations.

- Flint Group – A leader in flexographic plates and inks with sustainability at the core of its strategy.

- MacDermid Inc. – Offering robust photopolymer solutions for high-quality flexographic printing.

- Southern Lithoplate, Inc. – Specializing in lithographic plates designed for accuracy and durability.

- DuPont de Nemours, Inc. – Innovating across flexography and lithography with advanced plate-making solutions.

Beyond these established players, local and regional manufacturers are emerging as competitive forces. These companies are not only providing cost-effective alternatives but are also experimenting with new materials and plate technologies that address niche industry needs. Their agility and ability to adapt quickly to customer demands make them valuable contributors to the global printing ecosystem.

Regional Outlook: A Global Growth Story

The printing plate market is witnessing demand across multiple regions:

- North America – A mature market where innovation and sustainability drive adoption.

- Europe – Strong focus on eco-friendly printing technologies due to strict environmental policies.

- East Asia and South Asia – Rapidly growing hubs of packaging and consumer goods, fueling printing plate demand.

- Latin America – Increasing adoption of flexography for packaging in food and beverages.

- Middle East & Africa – Emerging opportunities driven by expanding retail and pharmaceutical sectors.

- Oceania – Moderate growth with rising interest in sustainable print technologies.

For more on their methodology and market coverage, visit! https://www.futuremarketinsights.com/about-us

Future Outlook: Printing Plates in a Digital Era

While digital printing continues to expand, traditional printing technologies remain vital, particularly in packaging, labeling, and branding. Printing plates will continue to play a critical role by offering scalability, consistency, and cost efficiency—attributes that digital alone cannot always match for large-volume jobs.

The future is likely to witness hybrid printing ecosystems, where digital and traditional methods co-exist. Printing plate manufacturers that align with this hybrid model—offering plates optimized for both conventional and digital workflows—will gain a significant competitive edge.

Related Reports:

Diaper Packaging Market: https://www.futuremarketinsights.com/reports/diaper-packaging-market

Plastic Jerry Can Industry Analysis in Malaysia: https://www.futuremarketinsights.com/reports/plastic-jerry-can-industry-analysis-in-malaysia

Gable Box Market: https://www.futuremarketinsights.com/reports/gable-box-market

Editor’s Note:

This release is based exclusively on verified and factual market content derived from industry analysis by Future Market Insights. No AI-generated statistics or speculative data have been introduced. This press release highlights significant shifts in the Printing Plate Market, which is experiencing a pivotal change driven by consumer demand for healthier, more transparent products.

Rahul Singh

Future Market Insights Inc.

+18455795705 ext.

email us here

Visit us on social media:

Other

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.