Physical AI for Inline Energy Optimization at Machine Level Market to Reach USD 11.4 Billion by 2036

Demand for physical AI for inline machine-level energy optimization is rising, driven by edge computing, real-time monitoring, and industrial efficiency needs.

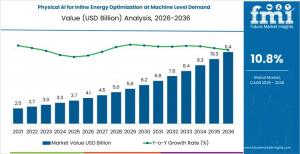

NEWARK, DE, UNITED STATES, January 20, 2026 /EINPresswire.com/ -- The global demand for Physical AI for Inline Energy Optimization at Machine Level is projected to reach USD 4.1 billion in 2026 and expand to USD 11.4 billion by 2036, registering a compound annual growth rate (CAGR) of 10.8%. Growth reflects rising enterprise investment in AI-driven, real-time energy management technologies that reduce operational costs while maintaining production performance across industrial environments.

Physical AI for inline energy optimization refers to the deployment of AI algorithms, sensors, and edge computing hardware directly at individual machines or production units. These systems analyze real-time energy consumption and operational parameters, enabling immediate optimization decisions without reliance on centralized cloud processing. Adoption is being driven by escalating energy costs, regulatory efficiency requirements, and corporate energy reduction commitments across manufacturing, process industries, and commercial infrastructure.

Enterprise Spending Focuses on Edge Intelligence and Machine-Level Control

Enterprise spending on physical AI for inline energy optimization is concentrated on infrastructure that enables low-latency, machine-level decision-making. A significant portion of investment flows toward edge computing hardware and AI processors capable of analyzing sensor data locally. These systems allow immediate adjustments to machine parameters based on operational demand, energy pricing, and efficiency targets.

Another major expenditure area includes sensor networks and data acquisition systems that monitor power consumption, thermal conditions, mechanical loads, and operational efficiency at the equipment level. Enterprises also allocate resources for integration with existing control systems, including programmable logic controllers (PLCs), distributed control systems (DCS), and manufacturing execution systems (MES), ensuring compatibility with established industrial infrastructure.

Ongoing spending supports operator training, technical enablement, cybersecurity, and data protection, enabling organizations to securely deploy AI-driven optimization while maintaining operational oversight. This comprehensive investment approach ensures that energy savings are measurable, verifiable, and sustainable over time.

Market Size Snapshot and Key Metrics

• Market value (2026): USD 4.1 billion

• Forecast value (2036): USD 11.4 billion

• CAGR (2026–2036): 10.8%

• Leading technology type: Edge-based optimization algorithms

• Fastest-growing applications: Manufacturing automation, process control systems, HVAC optimization

Edge-Based Optimization Leads Technology Adoption

By technology type, edge-based optimization algorithms account for 41.8% of total demand, reflecting their ability to process energy data locally and execute optimization decisions in real time. Real-time energy monitoring systems hold 27.5%, providing continuous measurement and efficiency insights during machine operation. Machine learning-based load prediction platforms represent 24.2%, supporting demand forecasting and optimized scheduling based on historical and production data. Automated control adjustment systems contribute 11.0%, while other optimization technologies account for the remainder.

Optimization functions further shape technology selection. Real-time energy consumption analysis represents 44.0% of demand, followed by automated parameter adjustment and control at 30.8%, predictive load management at 22.0%, and performance tracking and learning at 13.2%.

Manufacturing and Process Industries Drive Application Demand

By application, manufacturing automation and production equipment lead with 38.5%, as organizations seek continuous energy optimization across motors, drives, and processing equipment. Industrial process control systems account for 30.8%, particularly in energy-intensive operations such as heating, cooling, and chemical processing. HVAC and building systems represent 19.8%, while power generation, distribution, and research facilities account for the remaining share.

Adoption Follows Measured Savings Validation

Current deployments indicate an adoption horizon defined by measured energy savings validation rather than immediate full-scale rollouts. Early milestones include baseline energy consumption establishment, optimization algorithm validation, and controlled production deployment. Broader adoption accelerates once standardized deployment methodologies, validated savings models, and reusable configuration templates are established across similar equipment and facilities.

Global Demand Expands Across Major Industrial Economies

Globally, demand growth reflects increasing adoption of edge computing and AI-based control technologies. China leads with a 12.7% CAGR, followed by South Korea at 11.1%, the United States at 10.8%, Germany at 9.8%, and Japan at 9.0%. Across regions, adoption is driven primarily by energy cost reduction and efficiency improvement rather than technology advancement alone.

Explore trends before investing – request a sample report today! https://www.futuremarketinsights.com/reports/sample/rep-gb-31525

Competitive Landscape Anchored by Industrial Automation Leaders

The competitive ecosystem includes major industrial automation and energy management providers such as ABB Ltd., Schneider Electric SE, Siemens AG, General Electric Company, and Honeywell International Inc. Software, analytics, sensor suppliers, and system integrators play complementary roles, while standards bodies including IEC, IEEE, and ASHRAE influence procurement and validation practices.

Key Players in Physical AI for Inline Energy Optimization at Machine Level Demand

• ABB Ltd.

• Schneider Electric SE

• Siemens AG

• General Electric Company

• Honeywell International Inc.

Browse Related Insights

Fully Automatic High Speed Nail Making Machine Market: https://www.futuremarketinsights.com/reports/fully-automatic-high-speed-nail-making-machine-market

Self-Learning Machines for Material Flow Optimization Demand: https://www.futuremarketinsights.com/reports/self-learning-machines-for-material-flow-optimization-demand

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1,200 markets worldwide.

Sudip Saha

Future Market Insights Inc.

+18455795705 ext.

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.