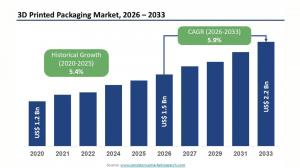

3D Printed Packaging Market to Reach US$2.2 Billion by 2033 Driven by Customization & Sustainable Packaging Innovation

3D-printed packaging is set to grow at a 5.9% CAGR through 2033, fueled by on-demand customization, new recyclable materials, and cheaper low-volume production

LONDON, LONDON, UNITED KINGDOM, January 20, 2026 /EINPresswire.com/ -- Introduction: The Rise of Additive Manufacturing in Packaging

The packaging industry is undergoing a technological transformation as brands seek innovative solutions to meet evolving consumer expectations and sustainability goals. Among the most disruptive advancements is 3D printed packaging, which enables customized, lightweight, and design-flexible packaging solutions. This technology allows manufacturers to produce packaging structures with intricate designs, reduced material waste, and faster prototyping capabilities. As digital manufacturing gains momentum, 3D printed packaging is steadily moving from concept-level innovation to commercial-scale application across multiple industries.

According to the latest study by Persistence Market Research, the global 3D printed packaging market size is likely to be valued at US$ 1.5 billion in 2026 and is expected to reach US$ 2.2 billion by 2033, growing at a CAGR of 5.9% between 2026 and 2033. This steady growth highlights rising adoption across food, pharmaceuticals, cosmetics, and consumer goods industries, where differentiation, efficiency, and sustainability have become key competitive priorities.

Get Your FREE Sample Report Instantly – Click Now: https://www.persistencemarketresearch.com/samples/36024

Market Growth Drivers: Customization and Brand Differentiation

One of the strongest growth drivers of the 3D printed packaging market is the increasing demand for customized packaging. Brands today seek distinctive packaging designs to enhance shelf appeal and customer engagement. Traditional packaging methods often limit design complexity and personalization, whereas 3D printing enables rapid production of unique shapes, textures, and branding elements. This capability is especially valuable in premium product segments where packaging directly influences purchasing decisions and brand perception.

In addition to customization, reduced time-to-market is another crucial factor driving adoption. 3D printing eliminates the need for costly molds and tooling, allowing faster design modifications and prototyping. This accelerates product launches while lowering development expenses. As companies aim to stay competitive in fast-changing consumer markets, the ability to quickly test and iterate packaging designs makes additive manufacturing a highly attractive solution.

Sustainability and Material Efficiency Transforming Packaging Practices

Sustainability has become a major concern in global packaging operations, and 3D printed packaging offers a promising solution. Conventional packaging production methods often result in excess material waste, whereas additive manufacturing builds structures layer-by-layer, using only the required material. This significantly reduces raw material consumption and supports corporate sustainability initiatives focused on waste minimization and resource efficiency.

Moreover, 3D printing enables the use of recycled and biodegradable materials, supporting the shift toward eco-friendly packaging alternatives. As regulatory pressure increases to limit plastic pollution and carbon emissions, businesses are exploring innovative production technologies that align with environmental standards. The ability to manufacture lightweight packaging also reduces transportation emissions, further strengthening the sustainability advantages of 3D printed packaging across global supply chains.

Market Segmentation: Understanding Key Industry Categories

By Material

Plastics

Paper & Paperboard

Aluminum

Others

By Technology

Stereolithography

Fused Deposition Modeling

Selective Laser Sintering

Multi Jet Fusion

Digital Light Processing

By Application

Food & Beverages

Pharmaceuticals

Cosmetics

Consumer Goods

Electronics

Industrial Goods

By Region

North America

Europe

East Asia

South Asia & Oceania

Latin America

Middle East & Africa

Get a Customized Market View in One Click: https://www.persistencemarketresearch.com/request-customization/36024

Technology Advancements Shaping Future Capabilities

Continuous advancements in 3D printing technologies are redefining packaging production capabilities. High-resolution techniques such as stereolithography and digital light processing enable the creation of smooth, detailed, and functional packaging designs. Meanwhile, fused deposition modeling and selective laser sintering allow strong structural packaging for industrial and logistics applications. These innovations are expanding the performance range of 3D printed packaging solutions.

Furthermore, integration of automation and AI-driven design software is improving production accuracy and reducing human intervention. Smart packaging concepts are also emerging, where 3D printed structures incorporate tracking codes, sensors, or tamper-evident features. As technology becomes more affordable and scalable, manufacturers are expected to increase investment in additive packaging systems to meet rising production demands and diversify packaging offerings.

Regional Insights: Growth Hotspots Across Global Markets

North America currently leads the 3D printed packaging market due to strong technological infrastructure, high R&D investment, and early adoption of digital manufacturing. The presence of major 3D printing solution providers and packaging innovators further strengthens regional growth. Europe follows closely, driven by strict sustainability regulations and rising demand for environmentally responsible packaging alternatives.

East Asia is emerging as a high-growth region, supported by expanding manufacturing capabilities and increased adoption of automation technologies. Meanwhile, South Asia & Oceania are witnessing growing interest as local industries explore cost-effective packaging innovation. Latin America and the Middle East & Africa are gradually adopting 3D printed packaging to enhance export-quality packaging standards and improve product differentiation in global markets.

Company Insights: Leading Players in the Competitive Landscape

Key players are focusing on improving printing speed, material compatibility, and cost efficiency to strengthen their market presence and meet evolving customer demands.

✦ HP Inc.

✦ Stratasys Ltd.

✦ 3D Systems Corporation

✦ Materialise NV

✦ EOS GmbH

✦ Carbon, Inc.

✦ Protolabs Inc.

✦ Formlabs, Inc.

✦ Desktop Metal, Inc.

✦ Markforged, Inc.

✦ Nexa3D

✦ BASF SE

✦ Evonik Industries AG

✦ Arkema S.A.

✦ SABIC

✦ GE Additive

✦ SLM Solutions Group AG

✦ Ricoh Company, Ltd.

For In-Depth Competitive Analysis, Buy Now: https://www.persistencemarketresearch.com/checkout/36024

Future Outlook: Innovation Driving Market Expansion

The future of the 3D printed packaging market looks promising as industries increasingly embrace digital manufacturing to enhance flexibility and sustainability. Ongoing improvements in printing speed, cost reduction, and material diversity will enable large-scale production in the coming years. As customization becomes a standard business strategy, 3D printed packaging will play a vital role in enabling brand uniqueness and consumer engagement.

Additionally, the convergence of smart technologies, sustainable materials, and automated production will reshape packaging supply chains. With steady growth projected at a CAGR of 5.9% from 2026 to 2033, the market is expected to witness broader adoption across industries. Companies investing early in additive packaging technologies will gain a competitive advantage in meeting future packaging demands efficiently and sustainably.

Explore the Latest Trending Research Reports:

Shrink Bags Market Survey

Track and Trace Packaging Market Survey

Ajaykumar Patil

Persistence Market Research

+1 6468786329

email us here

Visit us on social media:

LinkedIn

Instagram

Facebook

YouTube

X

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.